A question posted by a friend of KRISHNA – What do you do with pieces that get defective during the process of making Chikan-kari?

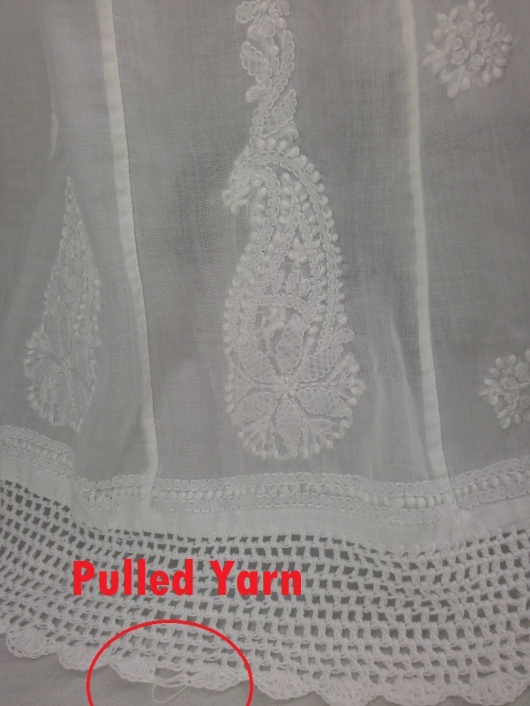

Let’s first understand the defects. The main defects that arise in almost all fabric garment industry are: 1.damage in cloth (torn, hole) 2.discolouration in final wash 3.weaving defect & 4.puled yarn (especialy in hand embroidered goods)

Jpeg

Chikan-kari is a process which passes through the human eye at every junction. The fabric is physically checked before sending it to cutting for weaving defects and damage. Then it goes to printing, then embroidery and finaly washing. In cases other than dress materials & sarees, stitching is also involved. Only washing is a process that is not responsible for any checks as the final piece is checked at the place where this journey started ie. the shop or workshop, otherwise the piece is stopped by any wise worker for further processes.

At the workshop, these final pieces come with the extra (left over / unused) thread that had been given at the time of sending the pieces for embroidery which serve a very important purpose. If wise people are involved, very little chances are that pieces will get torn. If a piece get torned a bit, it is darned and a booti (motif) is made with the extra thread i mentioned above. If the booti is looking out of place in a design, more bootis are added to the design to camouflage the original.

If discolouration occurs in washing which is 0.001% chance, such pieces are kept aside.

Weaving defects run throughout a piece if left unchecked in initial stage. If these are covered by the embroidery, there is no chance than to sell them off at any price at the soonest. But if a weaving defect is in an open space, these are also hidden by making embroidery in mirror pattern. Bail (long designs of creepers, etc.) blocks are printed on the defect & its mirror space and embroidered. So much extra thread is not availabe every time with a final piece, so matching thread is bought and the piece is embroidered again at the workshop or shop. After final wash if the two threads (old & new) don’t match, the piece is kept aside.

Hand (or even hand machine) embroidery is made by pulling the fabric in a loop frame. Then it is embroiderd. Sometimes the yarn gets pulled to one side especially in delicate cloths like muslin, georgettes, etc.

Jpeg

It is a common feature and does not harm the strength of the fabric. The pulled yarns go back to their initial place after 2-3 washes. This feature is un-avoidable / inevitable in making embroidery. Old buyers know it and don’t hesitate in buying such pieces but its a defect to a new customer. If the seller is able to convince these new customers, good, otherwise he / she knows that it will sell off eventually.

Now about the pieces that we had kept aside. The discoloured / mis-matched pieces are sent for dyeing. Different dyeing techniques like batik, tie-die, stone wash, spray dyeing have added to the beauty as well as saved the manufacturers from possible loss